Deeply embedded in the core of compressor technology:

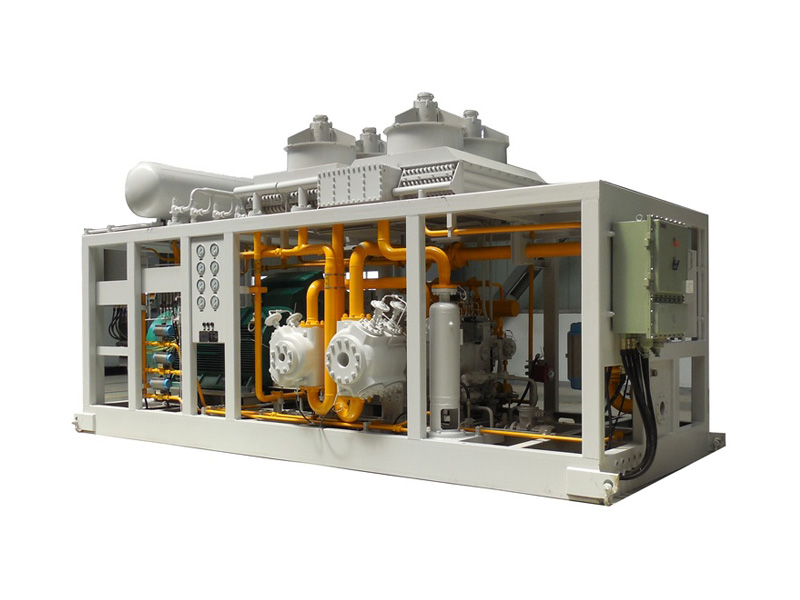

The technological evolution of Hydrogen Compressors is essentially a dual breakthrough in gas dynamics and materials science. When 30MPa high-pressure hydrogen is gradually pressurized between the impellers of a multi-stage centrifugal compressor, the compression ratio of each stage is precisely controlled at 1:3.2 to avoid the risk of hydrogen embrittlement caused by temperature rise. The 100MPa model released by IHI Corporation of Japan in 2024 uses a nickel-based high-temperature alloy impeller and a carbon fiber reinforced shell to push the working pressure to the 100MPa threshold, and the volume hydrogen storage density exceeds 80g/L. This ultra-high pressure compression technology is solving the pain points of long-distance transportation of green hydrogen: compared with 20MPa conventional compression, the 100MPa system expands the transportation radius of liquid hydrogen tank trucks by 400 kilometers and reduces costs by 57%.

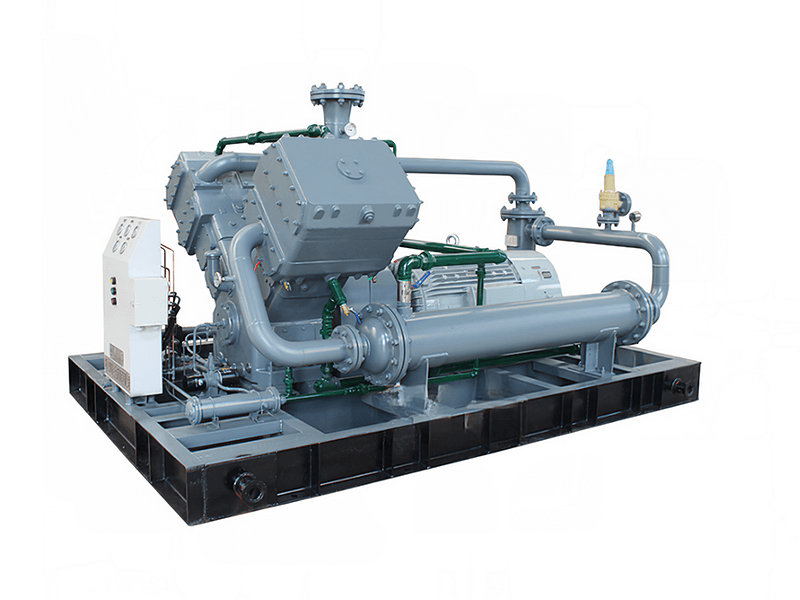

Innovation in compressor structure directly defines hydrogen storage efficiency. Kawasaki Heavy Industries' double-disc scroll compressor achieves zero leakage sealing at a pressure difference of 15MPa through phase difference meshing of the involute-shaped line reel. Its key breakthrough lies in the magnetic suspension bearing system: the rotor suspends and rotates in the electromagnetic field, and the mechanical loss is reduced to 5% of the traditional ball bearing, making the hydrogen filling rate exceed 120g/s (3 times higher than the piston type). The linear motor compressor developed by the German Linde Group completely eliminates the crankshaft structure and directly drives the piston through a linear motor, suppressing the vibration noise to below 45 decibels - this allows hydrogen refueling stations to enter the core area of the city.

The material revolution supports the extreme performance of the compressor. Faced with the hydrogen penetration corrosion of 0.15mm/year in the high-pressure hydrogen environment, Mitsubishi Heavy Industries deposits nanocrystalline diamond coating (NCD) on the impeller surface, with a Vickers hardness of 9000HV, reducing the wear rate to 0.001mm/10,000 hours. More cutting-edge is the ceramic-based composite material of Echogen in the United States: the silicon carbide fiber-reinforced impeller can operate continuously at 400°C, and with the active cooling system, the compressor energy efficiency ratio is increased to 8.2 - this is equivalent to only 0.98kWh of electricity per kilogram of hydrogen compressed.

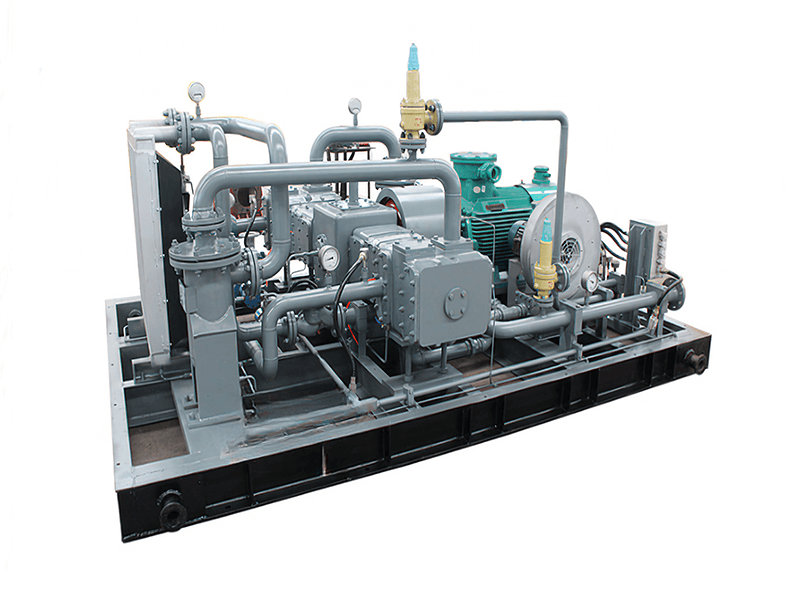

Intelligent control system has become the key to efficiency leap. The adaptive pressure control algorithm (APC-5.0) developed by Siemens for solid-state hydrogen storage compressors dynamically adjusts the compression ratio by real-time monitoring of the phase change enthalpy of the hydrogen storage alloy. When the sensor detects that the magnesium-based alloy reaches 80% saturation adsorption, the system automatically switches to low-pressure mode to avoid lattice collapse. This AI model has been verified at Sinopec Jiaxing Hydrogen Refueling Station: the filling efficiency is increased by 40% and the equipment life is extended by 2.8 times.

On the Norwegian zero-carbon freighter "Hydrogen Sea Messenger", the marine multi-stage compressor is creating a miracle in shipping history. Its four-stage compression module integrates a liquid nitrogen cryogenic system to compress 35MPa hydrogen to liquid density step by step, directly driving the dual-fuel engine. Wärtsilä engineer Ella Johnson recorded in the logbook: "When the compressor rolls 15 degrees, the pressure fluctuation is controlled at ±0.5MPa, which is ten times more stringent than the land standard." At the ArcelorMittal steel plant, industrial-grade hydrogen compressors are purifying and compressing the gray hydrogen in the coke oven gas and transporting it to the fuel cell fleet through underground pipelines. Each compressor has an annual processing capacity equivalent to 24,000 tons of green hydrogen, and the emission reduction benefits are equivalent to replanting 3,000 hectares of forest.

The cutting-edge laboratory is nurturing the next generation of technology. The supercritical carbon dioxide driven compressor announced by MIT uses the high density of sCO₂ to reduce compression power consumption by another 35%; the bionic pulsating compressor developed by the EU "Clean Sky" project imitates the vortex control principle of the humpback whale flipper, actively suppresses turbulence through the microcavity structure, and makes the efficiency exceed the Carnot limit of 12%. These breakthroughs will support the future of hydrogen energy predicted by the IEA: when the global compressor stock exceeds 1.2 million in 2030, the carbon emissions they reduce will account for 23% of the carbon neutrality target.